Shop Fitting

Shop Fitters often need to be able to produce a wide range of work. They not only need to manufacture cabinets and display shelving but often construct signage as well. Traditionally shop fitters have used a panel saw combined with a manual router, hand drill, point-to-point or any combination of these items to do their work. These methods are labour intensive and can be prone to human error.

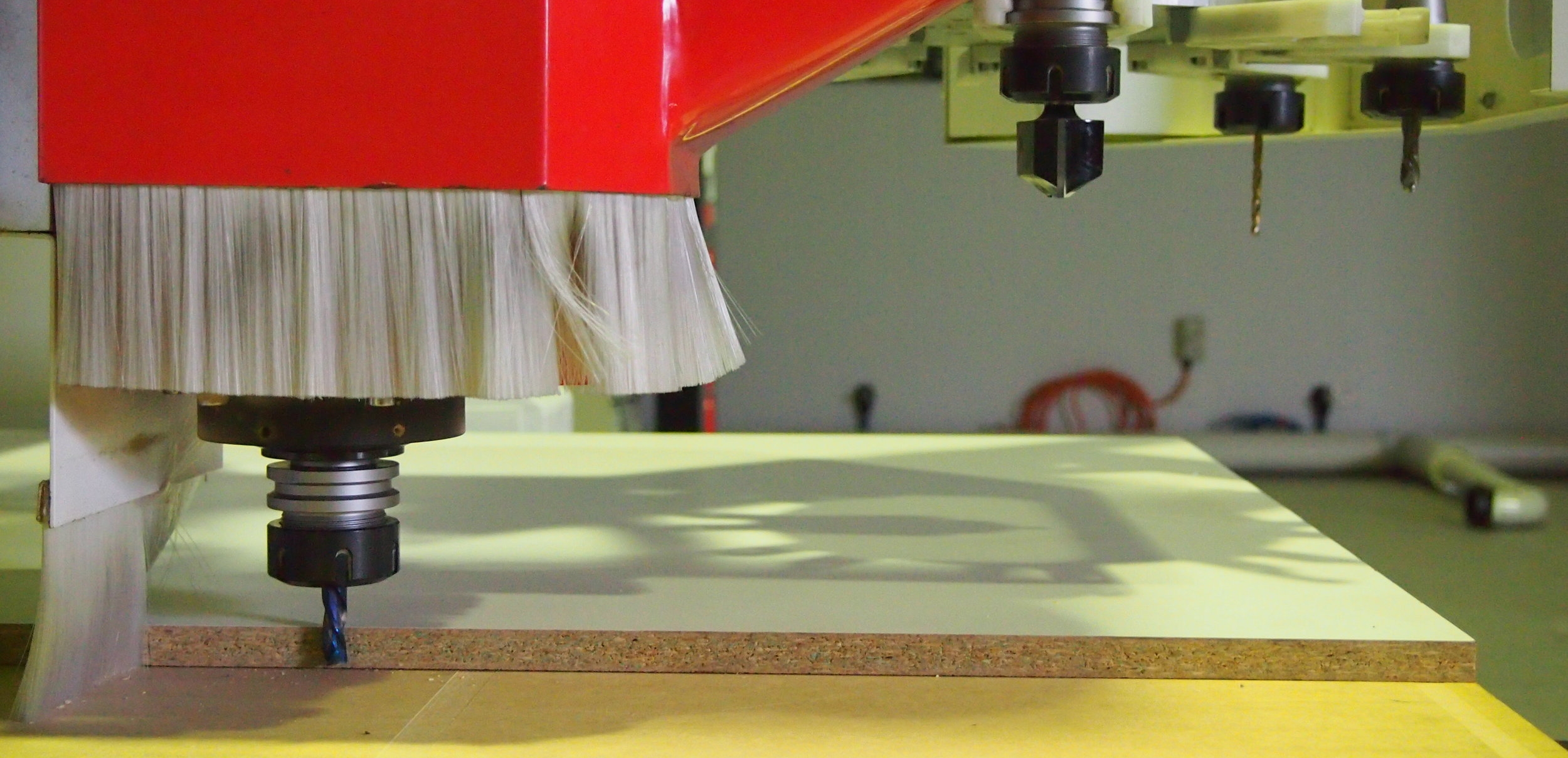

To handle shop fitting requirements a CNC Router must be fast, strong and durable. The Hurricane and Tornado are the work horses in our line-up. Some of the features that set them apart from a normal CNC Router are:

- Steel gantry and table construction

- Fast AC Servo drives on the X and Y axes

- Direct drive gearboxes – no belts to stretch or break

- Helical rack and pinion for superior accuracy

- Sealed THK bearings virtually eliminate grease requirements

With an Impact CNC Router shop fitters can cut out panels to an exact size, put construction and shelf holes in the right place, cut their own slat-wall, plus they can utilise the router to produce signage and display items for the store. One machine operator can do all the cutting and in many situations the operator can also do edge banding or sign construction while the next sheet is cutting. This frees up staff for assembly and installation work.

The level of automation depends on the requirements of the customer. Smaller shops will just need a standard router; however for medium to large shops we offer a range of options to further increase throughout. These options include:

- Sheet loading

- Static Rack Tool Changer or Carousel on the Gantry

- Multibore spindles for fast drilling of holes

- Sheet alignment pop-up pins